9832 HWY. 54 E

WISCONSIN RAPIDS, WI 54994

CALL: 800-472-4859 & 715-424-2148 FAX: 715-424-2162

Piston Diagnostic Guide

by Eric Gorr

The

process of examining a used piston can tell a mechanic helpful

information on the condition of an engine. When an engine failure

occurs, the piston is likely to take the brunt of the damage. A careful

examination of the piston can help a mechanic trace the source of a

mechanical or tuning problem. This technical article serves as a guide

for the most common mechanical problems that plague engines.

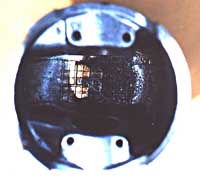

The crown of this piston shows an ideal carbon pattern. The transfer ports of this two-stroke engine are flowing equally and the color of the carbon pattern is chocolate brown. That indicates that this engine's carb is jetted correctly.

The underside of this piston has a black spot. The black spot is a carbon deposit that resulted from pre-mix oil burning on to the piston because the piston's crown was too hot. The main reasons for this problem are overheating due to too lean carb jetting or coolant system failure.

ASH TRASH

This piston crown has an ash color, which shows that the engine has run hot. The ash color is actually piston material that has started to flash (melt) and turned to tiny flakes. If this engine was run any longer, it probably would,ve developed a hot spot and hole near the exhaust side and failed. The main causes of this problem are too lean carb jetting, too hot spark plug range, too far advanced ignition timing, too much compression for the fuel's octane, or a general overheating problem.

SMASHED

DEBRIS

SMASHED

DEBRIS

This piston crown has been damaged because debris entered the combustion chamber and was crushed between the piston and the cylinder head. This engine had a corresponding damage pattern on the head's squish band. The common causes of this problem are broken needle bearings from the small or big end bearings of the connecting rod, broken ring ends, or a dislodged ring centering pin. When A problem like this occurs, its important to locate where the debris originated. Also the crankcases must be flushed out to remove any left over debris that could cause the same damage again. If the debris originated from the big end of the connecting rod, then the crankshaft should be replaced along with the main bearings and seals.

CHIPPED CROWN DROWNED

CHIPPED CROWN DROWNED

This piston crown chipped at the top ring groove because of a head gasket leak. The coolant is drawn into the combustion chamber on the down-stroke of the piston. When the coolant hits the piston crown it makes the aluminum brittle and it eventually cracks. In extreme cases the head gasket leak can cause erosion at the top edge of the cylinder and the corresponding area of the head. Minor leaks of the gasket or o-ring appear as black spots across the gasket surface. An engine that suffers from coolant being pressurized and forced out of the radiator cap's vent tube, is a strong indication of a head gasket leak. In most cases the top of the cylinder and the face of the cylinder head must be resurfaced when a leak occurs. Most mx bikes have head stays mounting the head to the frame. Over time the head can become warped near the head stay mounting tab, because of the forces transferred through the frame from the top shock mount. It's important to check for warpage of the head every time you rebuild the top end.

SHATTERED SKIRT

The skirts of this piston shattered because the piston to cylinder clearance was too great. When the piston is allowed to rattle in the cylinder bore, it develops stress cracks and eventually shatters.

SNAPPED ROD

The connecting rod of this engine snapped in half because the clearance between the rod and the thrust washers of the big end was too great. When the big end bearing wears out, the radial deflection of the rod becomes excessive and the rod suffers from torsion vibration. This leads to connecting rod breakage and catastrophic engine damage. The big end clearance should be checked every time you rebuild the top end. To check the side clearance of the connecting rod, insert a feeler gauge between the rod and a thrust washer. Check the maximum wear limits in your engine's factory service manual.

FOUR-CORNER SEIZURE

This piston has vertical seizure marks at four equally spaced points around the circumference. A four-corner seizure is caused when the piston expands faster than the cylinder and the clearance between the piston and cylinder is reduced. Another common problem of this type is a single point seizure on the center of the exhaust side of the piston. However this occurs only on cylinders with bridged exhaust ports. The main causes for this problem are too quick warm-up, too lean carb jetting (main jet), or too hot of a spark plug range.

MULTI-POINT SEIZURE

This piston has many vertical seizure marks around the circumference. This cylinder was bored to a diameter that was too small for the piston. As soon as the engine started and the piston started its thermal expansion, the piston pressed up against the cylinder walls and seized. The optimum piston to cylinder wall clearances for different types of cylinders vary greatly. For example a 50cc composite plated cylinder can use a piston to cylinder wall clearance of .0015 inches, whereas a 1200cc steel-sleeved cylinder snowmobile set-up for grass drags will need between .0055 to .0075 inches. For the best recommendation on the optimum piston to cylinder clearance for your engine, look to the specs that come packaged with the piston or consult your factory service manual.

INTAKE SIDE SEIZURE

This piston was seized on the intake side. This is very uncommon and is caused by only one thing, loss of lubrication. There are three possible causes for loss of lubrication, no pre-mix oil, separation of the fuel and pre-mix oil in the fuel tank, water passed through the air-filter and washed the oil film off the piston skirt.

Most

two-stroke cylinders used on motorcycles and snowmobiles, have

composite plated cylinders. The composite material is made of tiny

silicon carbide particles. The electro-plating process enables the

silicon carbide particles to bond to the cylinder wall. The particles

are very hard and sharp, they don't bond to the ports so the

manufacturer or reconditioning specialist must thoroughly clean the

cylinder. Sometimes the silicon carbide "flashing" breaks loose from

the ports and becomes wedged between the cylinder and the piston. This

causes tiny vertical scratches in the piston. This problem isn't

necessarily dangerous and doesn't cause catastrophic piston failure,

but it should be addressed by thoroughly flushing the cylinder and

ball-honing the bore to redefine the cross-hatching marks. Normally you

will need to replace the piston kit because the scratches will reduce

the piston's diameter beyond the wear spec.

BURNT-OUT BLOW-HOLE

This piston was overheated so badly that a hole melted through the crown and collapsed the ring grooves on the exhaust side. Normally the piston temperature is higher on the exhaust side so catastrophic problems will appear there first. There are several reasons for a failure like this, here are the most common; air-leak at the magneto side crankshaft seal, too lean carb jetting, too far advanced ignition timing or faulty igniter box, too hot of a spark plug range, too high of a compression ratio, too low octane fuel.

BLOW-BY

This piston didn't fail in operation but it does show the most common problem, blow-by. The rings were worn past the maximum ring end gap spec, allowing combustion pressure to seep past the rings and down the piston skirt causing a distinct carbon pattern. Its possible that the cylinder walls cross-hatched honing pattern is partly to blame. If the cylinder walls are glazed or worn too far, even new rings won't seal properly to prevent a blow-by problem. Flex-Hones is a product available at most auto parts stores. They can be used to remove oil glazing and restore cross-hatch honing marks that enable the rings to wear to the cylinder and form a good seal. If you purchase a Flex-Hone for your cylinder, the proper grit is 240 and the size should be 10% smaller than the bore diameter.

MAIN PAGE